Latest News

Latest News

Date:2024-05-20 20:43:48

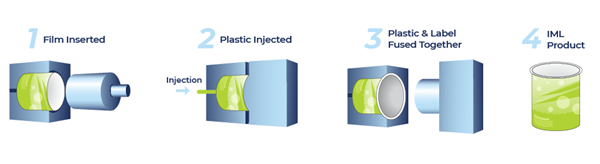

In-Mold Labeling (IML) is an advanced decoration technique in which a pre-printed polypropylene label (IML film) is placed inside the mold before the plastic container is formed. During molding, the molten plastic integrates with the label, resulting in a single, fully fused product.

This process eliminates the need for post-labeling and delivers a durable, scratch-resistant, and high-quality surface finish.

Unlike traditional labeling—where labels are applied after production—IML applies the label during manufacturing. This saves labor, improves production speed, and ensures consistent appearance and durability.

There are three main manufacturing techniques used in IML:

Injection Molding (Most common)

Blow Molding

Thermoforming

Injection molding is the most widely adopted method in IML. Heated thermoplastic or thermosetting polymers are injected into the mold containing a pre-positioned label.

As the plastic cools, the label becomes permanently bonded to the surface.

Typical Applications:

Food containers (butter, ice cream tubs)

Cosmetic packaging (skin cream jars)

Industrial packaging (paint buckets)

Electronics housings (keyboards, mobile keypads)

Although the process seems straightforward, precise control of molding temperature, injection pressure, label positioning, and cooling time is essential to achieve consistent quality. Understanding these parameters helps manufacturers choose reliable IML suppliers and optimize production efficiency.

Blow molding is ideal for hollow plastic containers. After the plastic is heated and extruded, air is blown into the preform so it expands to match the shape of the mold — including the label.

Typical Applications:

Shampoo bottles

Liquid soap containers

Food packaging (ketchup, sauces, beverage bottles)

This technique creates lightweight, strong containers with excellent printing and branding performance.

Thermoforming differs slightly from injection and blow molding. In this process, heated plastic sheets are shaped using a forming tool. The printed IML film is placed inside the mold and fuses to the plastic sheet during forming.

Typical Applications:

Disposable food trays

Dairy packaging

Single-use containers

Thermoforming is highly suitable for high-volume packaging with fast turnaround and lower material costs.

Previous:What Materials Are Used for In-Mold Labels?

Next:No More!